Tailoring Your Project Needs

with Titan™ Steel Solution

HOT ROLLED STEEL I BEAM

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED STEEL WIDE FLANGE I BEAM

Hot rolled steel wide flange I beams are the most common of all beams and are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish, non-tapered flanges, and a thicker center web for increased strength. Commonly used in the construction industry, steel wide flange beams are a standard structural material, primarily used to carry loads transverse to its longitudinal axis (web). Steel wide flange beams are often heavier than standard I beams or junior beams. ASTM A992 / A572-50 / A529-50 are the standard specifications for structural steel.

HOT ROLLED STEEL C CHANNEL

hot rolled steel c channels are an excellent candidate for most processing techniques. hot rolled steel channels have a rough, blue-grey finish. A36 material is a low carbon steel mild steel which is long lasting and durable. Hot rolled C channels have a “structural shape” meaning at least one dimension (excluding length) is greater than 3 inches. C channels inside flange surface have approximately a 16-2/3% slope, which distinguishes them from “MC” channels. Common applications include structural support, trailers, and other architectural uses.

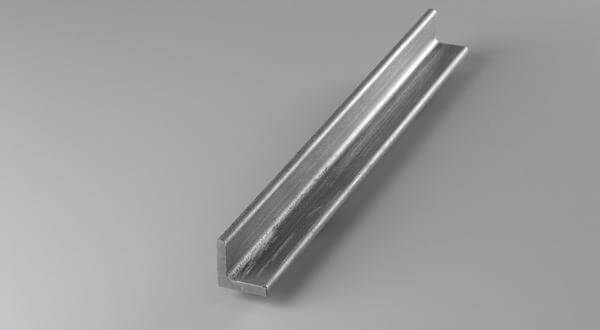

HOT ROLLED STEEL EQUAL LEG ANGLE

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED STEEL TEE BAR

Hot rolled steel equal leg angles are an excellent candidate for most processing techniques. hot rolled steel has a rough, blue-grey finish. material is a low carbon steel, often referred to as mild steel which is long lasting and durable. Common applications include structural support, trailers, bracing, and brackets.

STAINLESS STEEL CHANNEL

Stainless steel channel is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish and tapered legs. stainless steel is a high strength material with excellent corrosion resistance making it idea for walkways, ramps, and other architectural uses. ASTM A484 is the standard specification for general requirements for stainless steel billets and forgings.

STAINLESS STEEL ANGLE

Stainless steel equal leg angle is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish and tapered edges. stainless steel is a high strength material with excellent corrosion resistance making it ideal for shelves, brackets, bracing, and other architectural uses. ASTM A276-10 is the standard specification for structural stainless steel.

GALVANIZED STEEL CHANNEL

Hot-dipped galvanized steel channels are excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized channels are A36 hot rolled steel, or mild steel, channels that have been dipped into a molten zinc coating process (ASTM A123). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include heating and cooling systems, walkways, ramps, structural support, trailers and electrical protection.

GALVANIZED STEEL ANGLE

Hot-dipped galvanized equal leg angles are excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized angles are A36 hot rolled steel, or mild steel, angles that have been dipped into a molten zinc coating process (ASTM A123). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Galvanized angles have round or tapered edges. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include heating and cooling systems, mounting brackets, structural support, trailers and docks.

PIPE BOLLARDS

“ASTM A500 red primed steel pipe bollards are excellent candidate for asset protection settings. Steel pipe bollards can either be plate mounted or core installed. Coremark Metals offers pipe bollards that have been prefinished with a red primer. Common applications include equipment guarding, storefronts, sidewalks, and parking lots.

Pipe sizes are specified by two non-dimensional numbers. Nominal pipe size (NPS) or inside diameter (ID), and pipe schedule (SCH) referring to the wall thickness.”

BLACK STEEL PIPE

ASTM A53 black steel pipe, also referred to as ASME SA53 pipe, is an excellent candidate for most processing. Featuring a semi-smooth surface coated with black lacquer. Black steel pipe is intended for mechanical and pressure application. Common applications include steam, water, air, and gas systems. ASTM A53 is the standards specification covers seamless and welded, black and hot-dipped galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding.

A53 bare steel pipe sizes are specified by two non-dimensional numbers. Nominal pipe size (NPS) or inside diameter (ID), and pipe schedule (SCH) referring to the wall thickness.

DRAWN OVER MANDREL STEEL ROUND TUBE

A513 1020 drawn over mandrel (DOM) tubing an excellent candidate for most processing techniques. DOM tubing has a smooth black or dark brown uncoated finish with accurate dimensions throughout. DOM tubing is a welded tube with all flash removed making it a seamless tube. Designed for high strength close tolerances. Commonly used for axles, bushings, hydraulic cylinders and hinges. ASTM A513 is the standard specification for electric-resistance-welded carbon and alloy steel mechanical tubing.

BARE STEEL PIPE

ASTM A500 bare steel pipe is an excellent candidate for most processing. A500 bare steel pipes have a semi-smooth, uncoated grey finish. Bare steel pipe are not pressure tested, and primarily designed for structural use only. Common applications include railings, fencing, bollards, and gas systems. ASTM A500 is the standards specification for cold-formed welded and seamless carbon steel structural tubing in rounds and shapes.

A500 bare steel pipe sizes are specified by two non-dimensional numbers. Nominal pipe size (NPS) or inside diameter (ID), and pipe schedule (SCH) referring to the wall thickness.

MECHANICAL_STRUCTURAL STEEL SQUARE TUBE

Steel square tubing is an excellent candidate for most processing. Square steel tubing is available in A500 grade B or A513. Steel square tubes have a non-coated, semi-smooth grey finish. Mechanical/structural steel square tubing “wall thickness” has a tolerance of +/- 10%. Common applications include trailers, frames, shelves, and structural support. ASTM A500 is the standards specification for cold-formed welded and seamless carbon steel structural tubing in rounds and shapes. ASTM A513 is the standard specification for electric-resistance-welded carbon and alloy steel mechanical tubing.

MECHANICAL_STRUCTURAL STEEL RECTANGULAR TUBE

Steel rectangular tubing is an excellent candidate for most processing. Rectangle steel tubing is available in A500 grade B or A513. Rectangular square tubes have a non-coated, semi-smooth grey finish. Mechanical steel square tubing “wall thickness” has a tolerance of +/- 10%. Common applications include trailers, frames, shelves, and structural support. ASTM A500 is the standards specification for cold-formed welded and seamless carbon steel structural tubing in rounds and shapes. ASTM A513 is the standard specification for electric-resistance-welded carbon and alloy steel mechanical tubing.

STAINLESS STEEL ROUND TUBE

Stainless steel welded round tubing is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. Available in A269 or A554.This product has a semi-smooth, dull grey finish with accurate dimensions throughout length. stainless steel is a high strength material with excellent corrosion resistance making it ideal for liquid and/or chemicals passageways, railings, oil and gas lines, medical devices, and food processing. ASTM A269-10 is the standard specification for welded austenitic stainless steel tubing for general service. ASTM A554-21 is the standard specification for welded stainless steel mechanical tubing

STAINLESS STEEL RECTANGULAR TUBE

Stainless steel rectangular tubing is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This material has a textured dull grey finish with accurate dimensions throughout length. stainless steel is a high strength material with excellent corrosion resistance making it a great candidate for automotive fabrication, structural support, and sculptures. ASTM A554 is the standard specification for welded stainless steel mechanical tubing.

STAINLESS STEEL PIPE

Stainless steel welded pipe is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish with accurate dimensions throughout length. stainless steel is a high strength material with excellent corrosion resistance making it a great candidate for liquid passageways. ASTM A312 is the standard specification for seamless and welded stainless steel pipes. Stainless steel pipe dimensions are measured using inside dimensions (ID).

STAINLESS STEEL SQUARE TUBE

Stainless steel square tubing is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This non-magnetic product has a semi-smooth, dull grey finish and tapered edges with accurate dimensions throughout length. stainless steel is a high strength material with excellent corrosion resistance making it ideal for marine equipment, railings, medical devices, and food industry equipment. ASTM A554 is the standard specification for welded stainless steel mechanical tubing.

GALVANIZED STEEL PERFORATED SQUARE TUBE

Hot-dipped galvanized perforated square tube is an excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized perforated square tubes are hot rolled steel, or mild steel, tubes that have been punched and dipped into a molten zinc coating process. Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include shelving, brackets, outdoor signs, and adjustable posts due to its telescoping size options. Please see the available sizes table below for additional information on telescoping options.

GALVANIZED STEEL PIPE

Hot-dipped galvanized pipes are excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized pipes are A36 hot rolled steel, or mild steel, pipes that have been dipped into a molten zinc coating process (ASTM A123). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include potable water and drainage, fencing, posts, railing systems, and low pressure plumbing.

GALVANIZED STEEL SQUARE TUBE

Hot-dipped galvanized square tubing is an excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized square tubes are hot rolled steel, or mild steel, tubes that have dipped into a molten zinc coating process. Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include structural support, outdoor signs, docks, trailers, sign posts and framing.

STEEL REBAR

Steel rebar, or reinforcing bar, is an excellent candidate for most processing techniques. Steel rebar has a rough, blue-grey finish with raised ribs throughout the bar. Designed for use in concrete reinforcement, rebar increases the tensile strength of concrete structures.

HOT ROLLED STEEL JUNIOR BEAM

Hot rolled steel round bars are an excellent candidate for most processing techniques. Hot rolled steel round bars have a rough, blue-grey finish, dull rounded edges and have inexact dimensions throughout length. A36 material is a low carbon steel, often referred to as mild steel which is long lasting and durable. Common applications include shafts, railings, stakes, ornamental projects, and tines. ASTM A36 / A36M-08 is the standard specification for carbon structural steel.

COLD ROLLED STEEL ROUND BAR

Cold rolled steel round bars are an excellent candidate for most processing techniques. Cold rolled steel round bars have a smooth dark grey oiled surface, and accurate dimensions throughout. Cold roll bars have a higher tensile and yield strength compared to hot rolled bars. 1018 is a low carbon steel with good case hardening qualities. Designed for close tolerances, and commonly used for shafts, hinges and dowels. ASTM A108-07 is the standard specification for steel bar, carbon and alloy, cold-finished.

ANNEALED COLD ROLLED ROUND BAR

Cold rolled round bars are an excellent candidate for most processing techniques. Annealed cold roll bars is a high strength and abrasion resistant alloy. Extreme size accuracy, straightness and concentricity combine to minimize wear in high speed applications. Commonly used in gears, shafts, axles, bolts, studs and machine parts. Found within the automotive, defense, agriculture, aerospace, and oil and gas industries.

COLD ROLLED STEEL HEXAGON BAR

Cold rolled steel hexagon bars, or keystock, are an excellent candidate for most processing techniques. Cold rolled steel hexagon bars have a smooth dark grey oiled surface with sharp defined edges, and accurate dimensions throughout. 1018 cold roll bars have a higher tensile and yield strength compared to hot rolled bars. 1018 is a low carbon steel with good case hardening qualities. Designed for close tolerances, and commonly used for machining, shafts, gears and sprockets. ASTM A108-07 is the standard specification for steel bar, carbon and alloy, cold-finished.

HOT ROLLED STEEL SQUARE

Hot rolled steel square bars, or keystock, is an excellent candidate for most processing techniques. Hot rolled steel square bars have a rough, blue-grey finish, dull rounded edges and have inexact dimensions throughout length. A36 material is a low carbon steel, often referred to as mild steel which is long lasting and durable. Common applications include shafts, railings, stakes, ornamental projects, and tines. ASTM A36 / A36M-08 is the standard specification for carbon structural steel.

COLD ROLLED STEEL SQUARE BAR

Cold rolled steel square bars are an excellent candidate for most processing techniques. Cold rolled steel square bars have a smooth dark grey oiled surface, and accurate dimensions throughout. Cold roll bars have a higher tensile and yield strength compared to hot rolled bars. 1018 is a low carbon steel with good case hardening qualities. Designed for close tolerances, and commonly used for shafts, hinges and dowels. ASTM A108-07 is the standard specification for steel bar, carbon and alloy, cold-finished.

A36 HOT ROLLED STEEL FLAT BAR

Hot rolled steel flat bars, or flat stock, are an excellent candidate for most processing techniques. Hot rolled steel flat bars have a rough, blue-grey finish, dull rounded edges and have inexact dimensions throughout length. A36 material is a low carbon steel, often referred to as mild steel which is long lasting and durable. Common applications include shelving, sculptures, trim, bracing, and brackets. ASTM A36 / A36M-08 is the standard specification for carbon structural steel.

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

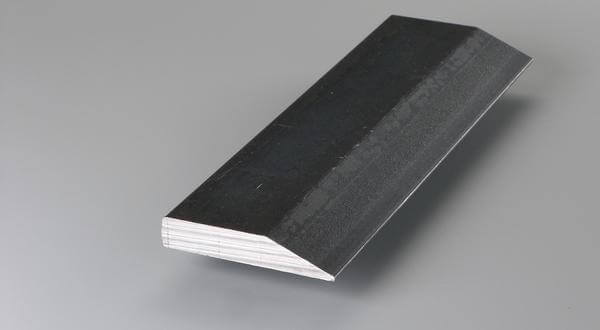

STEEL BEVELED CUTTING EDGE

Hot rolled steel beveled cutting edges are manufactured from 1055 hardened steel to meet the demands in the toughest environments. A1055 hot rolled steel beveled cutting edges have a rough, blue-grey finish with tapered edges. Designed to be welded or bolted onto tractors or skid steer buckets, and plows to increase work productivity.

COLD ROLLED STEEL FLAT BAR

Cold rolled steel flat bars, or flat stock, are an excellent candidate for most processing techniques. Cold rolled steel flat bars have a smooth dark grey oiled surface with sharp defined edges, and accurate dimensions throughout. 1018 cold roll bars have a higher tensile and yield strength compared to hot rolled bars. 1018 is a low carbon steel with good case hardening qualities. Designed for close tolerances, and commonly used for machining, jigs and templates. ASTM A108-07 is the standard specification for steel bar, carbon and alloy, cold-finished.

STAINLESS STEEL ROUND BAR

Stainless steel cold drawn round bar is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product, designed for close tolerances, has a semi-smooth, dull grey finish with accurate dimensions throughout length. Stainless steel is a high strength material with excellent corrosion resistance making it ideal for shafts, hinges, dowels and other structural applications. ASTM A314 is the standard specification for stainless steel billets and bars for forging.

STAINLESS STEEL SQUARE BAR

Stainless steel square bar is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product, designed for close tolerances, has a semi-smooth, dull grey finish and sharp defined edges with accurate dimensions throughout length. Stainless steel is a high strength material with excellent corrosion resistance making it ideal for structural support, shafts, jigs, key stock, sculptures, and other architectural uses. ASTM A276-10 is the standard specification for stainless steel bars and shapes.

STAINLESS STEEL FLAT BAR

Stainless steel flat bar or “flat stock” is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish and sharp defined edges with accurate dimensions throughout length. Stainless steel is a high strength material with excellent corrosion resistance making it ideal for shelves, brackets, bracing, sculptures, and other architectural uses. Also found within the food and beverage industry, aerospace applications, and chemical processing. ASTM A276-10 is the standard specification for structural stainless steel.

GALVANIZED STEEL ROUND BAR

Hot-dipped galvanized round bar is an excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized round bars are A36 hot rolled steel, or mild steel, round bars that have been dipped into a molten zinc coating process (ASTM A123). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Galvanized round bars are semi-rough with dull edges, and are inexact dimensions throughout length. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include hinges, railing systems, and ground stakes.

GALVANIZED STEEL FLAT BAR

Hot-dipped galvanized flat bar or “flat stock” is an excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized flat bars are A36 hot rolled steel, or mild steel, flat bars that have been dipped into a molten zinc coating process (ASTM A123). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include shelving, brackets, sculptures, bracing, trim, and trailers.

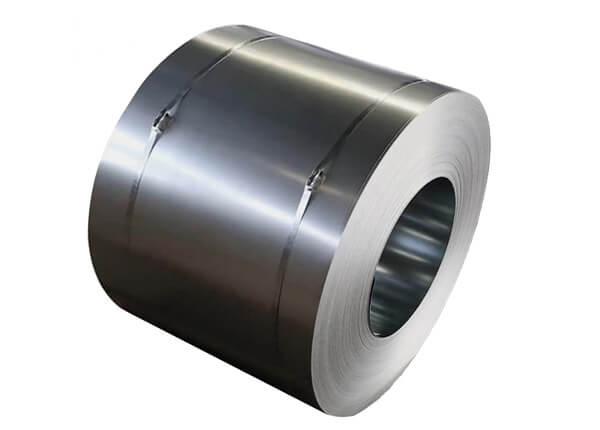

HOT ROLLED STAINLESS STEEL COIL

Hot rolled steel sheets are an excellent candidate for most processing techniques. Hot rolled steel sheets have smooth, blue-grey finish. A1011 is considered a commercial quality alloy material. Common applications include base plates, brackets, gusset, sheathing and ornamental projects. ASTM A1011 is the standard specification for steel, sheet, strip, hot rolled, carbon, structural, high strength low alloy, high strength low alloy with improved formability and ultra-high strength.

COLD ROLLED STAINLESS STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

LOW CARBON STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

BLACK MILD CARBON STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

GALVANIZED STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

GALVALUME STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

PRE PAINTED GALVANIZED STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

COLD ROLLED CHECKERED STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED CHECKERED STEEL COIL

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

PICKLED AND OILED STEEL SHEET

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

ABRASION RESISTANT STEEL PLATE

Abrasion resistant steel plate is a good candidate for some processing techniques. This material is characterized by a smooth, blue-grey-red finish with a hardened surface and while not a good candidate for forming and machining AR200 plate is suitable for welding. Intended for moderate wear applications, common uses include contact surfaces, hoppers, cement mixer drums and fins, and screw conveyors. ASTM A514 is the standard specification for high yield, quenched and tempered alloy steel plate.

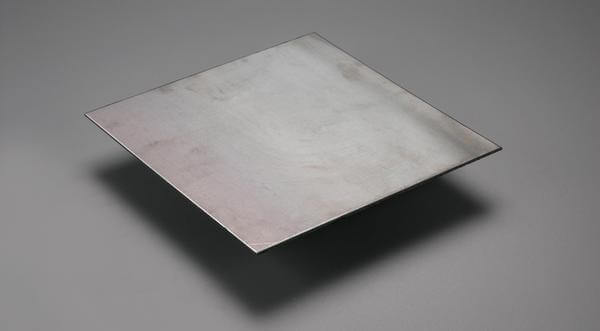

COLD ROLLED SHEET

Cold rolled steel sheets are an excellent candidate for most processing techniques. Cold rolled steel sheets have an oiled, smooth, grey finish. A1008 is considered a commercial quality alloy material. Common applications include brackets, gussets, body panels and ornamental projects. ASTM A1008 is the standard specification for steel, sheet, cold-rolled, carbon, structural, high-strength low-alloy, with improved formability and solution hardened.

HOT ROLLED STEEL FLOOR PLATE

Hot rolled steel floor plate is a commercial quality material that is an excellent candidate for most processing technique. Hot rolled steel floor plate is also known as “tread plate or diamond plate.” Hot rolled steel floor plate has a textured blue-grey finish with a raised diamond pattern to provide all around traction. Common applications include catwalks, trench covers, walkways and ornamental projects. ASTM A786 is the standard specification for hot-rolled carbon, low-alloy, high strength low-alloy, and alloy steel floor plates.

WEATHERING STEEL SHEET

Weathering steel sheet is a high strength material designed to develop a rust-like surface patina if left unfinished, eliminating the need to paint the material and protecting the material from corrosion. Weathering steel is intended for welded, bolted, or riveted construction and common applications include landscaping, retaining walls, planter boxes, outdoor sculptures, building exteriors, electrical power poles, railcars, and other structures where high strength and enhanced corrosion resistance are required.

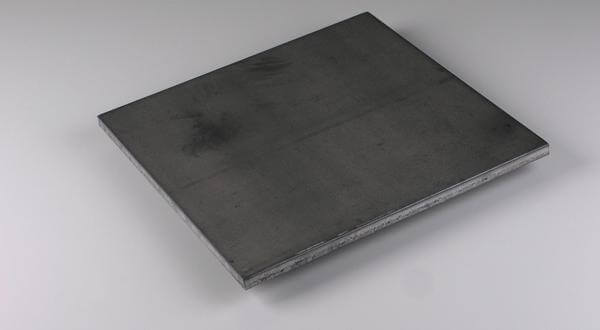

HOT ROLLED STEEL PLATE

Hot rolled steel plates are an excellent candidate for most processing techniques. Hot rolled steel plates have a rough, blue-grey finish, dull rounded edges and have inexact dimensions throughout length. Material is a low carbon steel, often referred to as mild steel which is long lasting and durable. Common applications include base plates, brackets, gussets and trailer fabrication. ASTM A36 / A36M-08 is the standard specification for carbon structural steel.

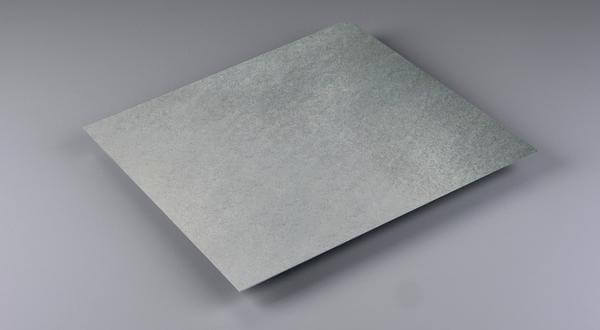

GALVANIZED STEEL SHEET

Hot-dipped galvanized steel sheets are excellent candidate for most processing techniques. Welding, torching, or abrasive sawing galvanized steel is not recommended without proper protection and adequate ventilation. Galvanized hot rolled steel, or mild steel, sheets have been dipped into a molten zinc coating, or zinc-iron alloy-coated (galvannealed) by the hot-dipped process (ASTM A653). Hot-dipped galvanize (HDG) can be identified by its crystallization pattern, also known as “spangle” on the surface of the material. Great corrosion resistance, excellent candidate for outdoor use or exposed environments. Common applications include HVAC, flashing, freezers, commercial and architectural uses, electrical boxes, enclosures and housings.

STAINLESS STEEL FLOOR PLATE

Stainless steel floor plate, also known as “tread plate” or “diamond plate”, is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a textured dull grey finish with a raised diamond pattern to provide all around traction. Stainless steel floor plate has a hot rolled, annealed and pickled (HRAP) finished surface. Its high strength properties and excellent corrosion resistance make it the perfect candidate for catwalks, trench covers, walkways, and ornamental projects. ASTM A793 is the standard specification for stainless steel rolled floor plate.

304 STAINLESS STEEL FLOOR PLATE

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED CIRCULAR BASE PLATES

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED CASTER BASE PLATE

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED GUSSET PLATES

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED HOLLOW GUSSET PLATES

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

HOT ROLLED I HOOKS

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

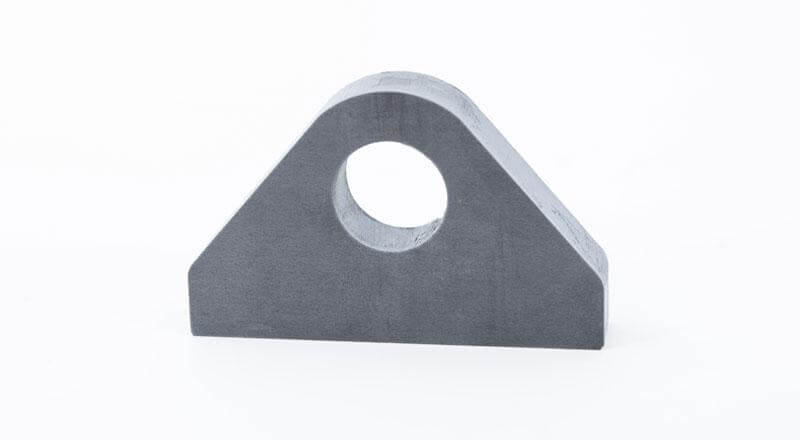

HOT ROLLED LIFTING LUG

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

PICKLED AND OILED STEEL CIRCLES

Hot rolled steel I beams are an excellent candidate for most processing techniques. They are often characterized by a textured blue-grey finish and tapered flanges against the web for increased strength. Commonly used in the construction industry, steel I beams are a standard structural material primarily used to carry loads transverse to its longitudinal axis (web). ASTM A992 / A572-50 are the standard specifications for structural steel.

Get Best Steel Prices with Titan™ Solution or Your Money Back.

Discover How Titan™ Sources Quality Steel at Unbeatable Prices. Book Free Consultation Now.

Contact Us Today

After we get some information from you, we’ll set up a time to discuss your project in further detail.